Components for Furnaces Installed in Aerospace Companies: Quality Standards and Advanced Materials

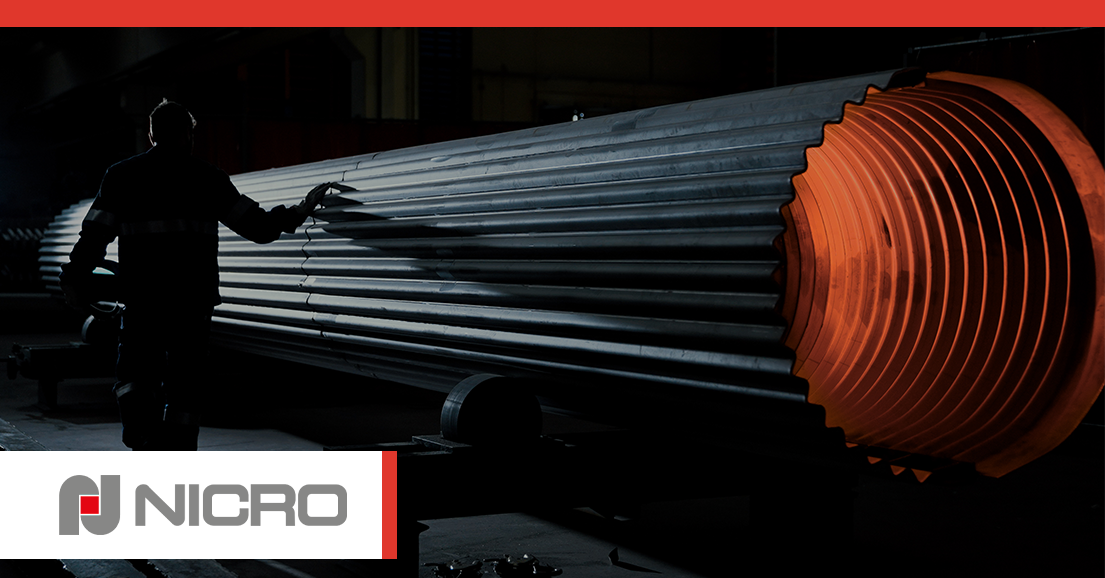

Among Nicro’s various clients, those in the aerospace industry stand out a niche market that demands extremely high standards for both product quality and reliability. Aerospace clients require a commitment to excellence in materials and adherence to stringent regulations. Although Nicro does not produce aircraft components or directly manufacture aerospace parts, it is a key player in the sector, specializing in the production of bell furnaces, retorts, funs and furnace equipment for the heat treatment of aerospace components.

With over half a century of experience in heat treatment, Nicro manufactures products using high-nickel steel alloys, setting itself apart with the high quality of its components, supported by a rigorous certification process and deep expertise in nickel alloys and high-temperature stainless steels.

These materials ensure that bell furnaces, retorts, funs and furnace equipment for heat treatment furnaces can withstand extreme mechanical, chemical, and thermal conditions. What truly makes Nicro unique, however, is its customer-oriented approach: each solution is customized to meet the specific needs of each company, thereby enhancing the efficiency, durability, and productivity of their systems.

Types of Components Produced

Our product range includes various components for industrial furnaces. Key products made for companies in the aerospace sector include:

- Bell Furnaces: Structures used to contain heat and protect materials during heat treatment processes, essential for ensuring separation between the controlled and protected furnace atmosphere and the external environment. Their design requires special attention to heat distribution and mechanical strength.

- Retorts: Used for heating materials in controlled environments, retorts are chambers designed to maximize thermal efficiency and minimize heat loss. The use of nickel alloys enhances resistance to oxidation and wear.

- Fans: Nicro has extensive experience in the production of high-temperature convection fans, custom-designed with innovative construction solutions that include variable thicknesses. These fans are specifically designed to withstand the stress they endure during operation.

- Heat Treatment Equipment: Nicro was originally founded to produce equipment for heat treatment in atmospheric and vacuum conditions, and it is now capable of providing various types of products, supporting clients with development and design calculations. Among the products offered are lifting equipment, grids, and baskets.

The quality of the finished product is crucial, as the components we produce must withstand highly demanding operational conditions, enabling our clients to meet the highest standards. Every stage of production is carefully monitored to ensure that all technical specifications are met, delivering a product that not only meets but exceeds client expectations.

High-temperature stainless steels and nickel alloys are selected not only for their mechanical properties but also for their compatibility with high-performance applications in the aerospace sector.

Quality Certifications

The stringent regulations governing aerospace finished products require our clients to comply with high international quality standards. Nicro, with ISO 9001:2015 and ISO 3834-2 certifications, attests to an effective quality management system and production processes that meet customer needs and rigorous industry regulations.

Through a stringent selection process, we ensure collaboration with only the most qualified and competent partners. We particularly focus on suppliers involved in welding processes, partnering exclusively with certified and experienced collaborators to meet specific technical standards and regulations.

Additionally, where necessary, Nicro’s equipment can be designed and manufactured in compliance with Directive 2006/42/EC and standards UNI EN ISO 12100 and UNI EN ISO 13857. These address essential aspects of equipment safety and design, ensuring that each product is not only functional but also safe for operators.

Each piece of equipment provided by Nicro is accompanied by a Quality Dossier, which, beyond legal documentation, may include, upon request, a CE declaration of conformity, calculation reports, risk analysis, user and maintenance manuals, and testing reports. This dossier provides transparency on product quality and gives clients the assurance needed to use our components in critical industrial environments.

Our Future with clients in the Aerospace Sector

In recent years, Nicro has consistently invested in enhancing its production capabilities and expanding its presence in the aerospace market. Although our company already collaborates with clients both in Italy and internationally, our goal is to further broaden our offerings, emphasizing the quality and reliability of our products and services.

We aim to continually improve our production technologies and develop new processes using increasingly high-performance materials to meet the emerging needs of the sector. Investing in R&D allows us to remain competitive and innovative, establishing ourselves as reliable partners for aerospace clients, recognized for the excellence of our components and our ability to meet specific customer requirements.

Contact us for more information and take advantage of Nicro’s extensive experience in the field of heat treatments.