Simulation and Technical Consulting: How Nicro Optimizes Solutions for Its Clients

In industries such as steel, chemical, oil and gas, and pharmaceutical chemistry, technical consulting is essential to ensure reliable and long-lasting solutions. When a client faces a problem, such as the deterioration of a component or the need to verify its resistance under specific operating conditions, relying solely on hypotheses or past experiences is not enough. Each manufactured component is subjected to unique stresses, which can vary depending on factors such as temperature, corrosion, and mechanical stress.

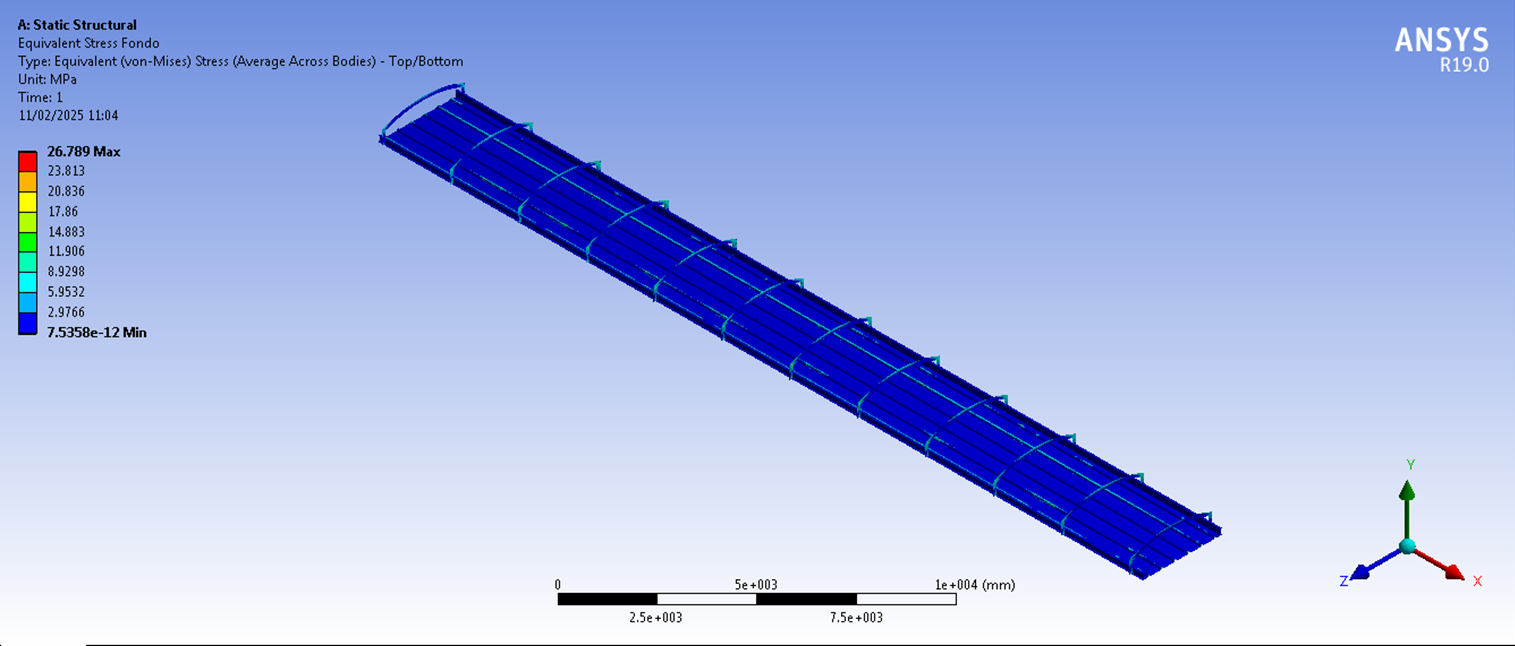

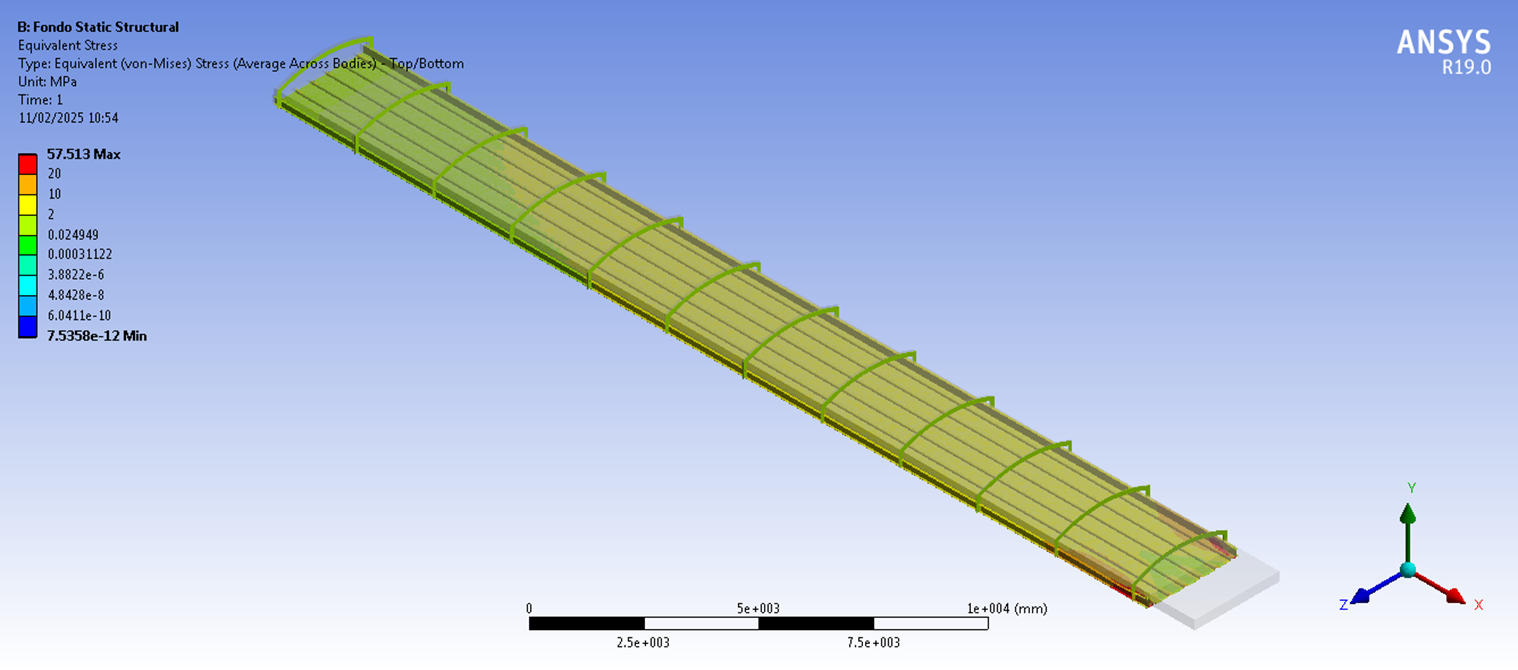

For this reason, at Nicro, we adopt a data-driven approach supported by advanced simulation tools. By using ANSYS software, we can perform detailed analyses of proposed solutions, verifying their effectiveness before physically intervening on the component.

What is ANSYS and Why is it a Fundamental Tool?

ANSYS is one of the most powerful simulation software programs in mechanical and structural engineering. Thanks to its advanced algorithms, it allows predictive analysis of factors such as:

- Mechanical strength: Verifying the component’s ability to withstand loads and stresses.

- Thermal effects: Simulating thermal expansion and structural variations due to high temperatures.

- Corrosion resistance: Analyzing the durability of materials in chemically aggressive environments.

- Material fatigue: Predicting wear and deterioration over time.

This means that before intervening on a component, we can simulate its behavior in detail to anticipate potential critical issues. As a result, we provide our clients with not only more precise consulting but also significant cost savings by reducing the risk of errors and corrective interventions.

How the Analysis and Simulation Process Works

The process begins with a data collection phase, during which we analyze the component under study, evaluating its material, geometry, and operating conditions. To obtain accurate results, it is essential to have detailed information, such as operating temperature, applied mechanical loads, and the presence of any corrosive agents. The more precise the data provided, the more realistic the simulation results will be.

Once all necessary information has been gathered, the component model is imported into ANSYS software. Here, we run various simulations to assess the material’s behavior under real operating conditions. We analyze structural resistance, evaluating the component’s ability to withstand mechanical stresses, and test its response to thermal variations to verify potential deformations caused by high temperatures. If the component is exposed to corrosive substances or particularly aggressive environments, we examine its corrosion resistance, estimating its wear over time. Additionally, through fatigue testing, we simulate the component’s long-term behavior, identifying potential critical points due to repeated stress.

From the simulation results, we obtain a clear evaluation of the effectiveness of the proposed solution. If the tests confirm that the planned intervention is effective, we proceed with implementation. If critical issues arise, we optimize the project by modifying the solution to enhance its performance. This approach prevents interventions based on simple assumptions and ensures highly reliable solutions, reducing the risk of errors and optimizing both time and costs.

The Advantages of ANSYS Analysis for Our Clients

The integration of ANSYS software into Nicro’s technical consulting brings numerous tangible benefits to clients, enhancing the reliability of proposed solutions and reducing the margin of error. One of the most significant advantages is the ability to validate design assumptions before their application, avoiding interventions based solely on experience or assumptions. Thanks to simulations, we can predict with high precision how a component will behave under real conditions, identifying potential issues in advance and optimizing solutions before physically modifying the piece.

Another key benefit is the reduction of costs associated with evaluation errors. Without a thorough analysis, a repaired or modified component might not perform as required, leading to additional corrective actions, extra expenses, and extended plant downtime. With ANSYS, however, every decision is backed by concrete data, allowing for more secure interventions and avoiding unforeseen costs.

From a safety and reliability perspective, this methodology ensures that the analyzed component meets the required specifications, both in terms of mechanical resistance and long-term durability. For clients, this translates into greater peace of mind and the certainty of receiving a highly professional service capable of delivering truly effective solutions.

Thus, ANSYS is not merely a support tool but an added value that enables Nicro to provide advanced technical consulting services. This approach minimizes the risk of unexpected failures, optimizes intervention times, and guarantees clients high-performance, long-lasting solutions.

Innovation as a Pillar of Nicro’s Philosophy

The integration of ANSYS software into the technical consulting process is not just an operational advantage; it is a key element of Nicro’s philosophy. The company has always invested in technological innovation to provide clients with advanced and highly reliable solutions.

For Nicro, innovation means combining experience and technology to meet the increasingly complex demands of the industry. The ability to virtually test solutions before implementation reduces time and material waste while offering clients a service based on concrete data rather than assumptions. This approach enhances the reliability of interventions, leading to more predictable and measurable results.

The use of ANSYS and other advanced technologies reaffirms Nicro’s commitment to a more sustainable and efficient industry while continuing to provide clients with the highest level of expertise and technological innovation. The ability to accurately predict a component’s behavior reduces unnecessary interventions, limits resource consumption, and promotes smarter, more responsible material management. Innovation is not just about improving technical performance; it also involves adopting a more sustainable work model aligned with the evolving needs of the industrial market.

Thus, innovation is not just a goal but a working method that guides every phase of Nicro’s operations.